Economical, Versatile Storage for Outside or In-Plant Use

Whether you need outside or in-plant bulk storage, a BROCK® Bulk Storage System offers a versatile line of economical bolted-steel hopper-bottom silos in the capacities and features you need today – in a silo that will allow you to grow into tomorrow.

More

Capacities range from 35 through 6,800 cubic feet (1 through 193 cubic meters). Silo diameters range from 6 to 18 feet (1.8 to 5.5 meters).

The sturdy, low-profile (10-degree slope) roof has a 22-inch (56 cm) fill opening and 12-inch (305 mm) discharge opening with 16×16-inch (41×41 cm) universal flange.

Unskirted silos are available with optional safety cages, lockable doors and crosswalks designed to meet OSHA specifications.

Other options include:

- Rooftop perimeter guard and toe board

- Manholes

- Pressure relief valves

- View windows

Unskirted Storage Silos

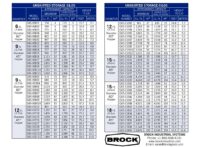

| Diameter Feet (Meters) | Model Number | Approx. Capacity Maximum Cu. Ft. | Approx. Capacity Maximum M3 | Usable Capacity Cu. Ft.* | Usable Capacity M3* | Height To Lid Feet | Height To Lid Meters |

|---|---|---|---|---|---|---|---|

| 60° Hopper Angle | |||||||

| 6 ft. (1.8 m) | C45-00601 | 124 | 4 | 113 | 3 | 10.2 | 3.1 |

| 6 ft. (1.8 m) | C45-00602 | 199 | 6 | 188 | 5 | 12.8 | 3.9 |

| 6 ft. (1.8 m) | C45-00603 | 273 | 8 | 262 | 7 | 15.5 | 4.7 |

| 6 ft. (1.8 m) | C45-00604 | 348 | 10 | 337 | 10 | 18.2 | 5.5 |

| 6 ft. (1.8 m) | C45-00605 | 423 | 12 | 412 | 12 | 20.8 | 6.3 |

| 6 ft. (1.8 m) | C45-00606 | 497 | 14 | 486 | 14 | 23.5 | 7.2 |

| 45° Hopper Angle | |||||||

| 9 ft. (2.7 m) | C45-00932 | 439 | 12 | 385 | 11 | 13.0 | 4.0 |

| 9 ft. (2.7 m) | C45-00933 | 608 | 17 | 554 | 16 | 15.8 | 4.8 |

| 9 ft. (2.7 m) | C45-00934 | 777 | 22 | 723 | 20 | 18.5 | 5.6 |

| 9 ft. (2.7 m) | C45-00935 | 946 | 27 | 892 | 25 | 21.2 | 6.5 |

| 9 ft. (2.7 m) | C45-00936 | 1,115 | 32 | 1,061 | 30 | 23.8 | 7.3 |

| 9 ft. (2.7 m) | C45-00937 | 1,284 | 36 | 1,230 | 35 | 26.4 | 8.0 |

| 9 ft. (2.7 m) | C45-00938 | 1,453 | 41 | 1,399 | 40 | 29.0 | 8.8 |

| 9 ft. (2.7 m) | C45-00939 | 1,622 | 46 | 1,568 | 44 | 31.7 | 9.7 |

| 9 ft. (2.7 m) | C45-009310 | 1,791 | 51 | 1,737 | 49 | 34.3 | 10.5 |

| 9 ft. (2.7 m) | C45-009311 | 1,960 | 56 | 1,906 | 54 | 37.0 | 11.3 |

| 60° Hopper Angle | |||||||

| 9 ft. (2.7 m) | C45-00902 | 514 | 15 | 460 | 13 | 16.0 | 4.9 |

| 9 ft. (2.7 m) | C45-00903 | 684 | 19 | 630 | 18 | 18.6 | 5.7 |

| 9 ft. (2.7 m) | C45-00904 | 854 | 24 | 800 | 23 | 21.3 | 6.5 |

| 9 ft. (2.7 m) | C45-00905 | 1,019 | 29 | 965 | 27 | 24.0 | 7.3 |

| 9 ft. (2.7 m) | C45-00906 | 1,189 | 34 | 1,135 | 32 | 26.6 | 8.1 |

| 9 ft. (2.7 m) | C45-00907 | 1,359 | 38 | 1,305 | 37 | 29.3 | 8.9 |

| 9 ft. (2.7 m) | C45-00908 | 1,529 | 43 | 1,475 | 42 | 31.9 | 9.7 |

| 9 ft. (2.7 m) | C45-00909 | 1,699 | 48 | 1,645 | 47 | 34.6 | 10.5 |

| 9 ft. (2.7 m) | C45-009010 | 1,869 | 53 | 1,815 | 51 | 37.3 | 11.4 |

| 45° Hopper Angle | |||||||

| 12 ft. (3.7 m) | C45-01232 | 803 | 23 | 662 | 19 | 14.9 | 4.5 |

| 12 ft. (3.7 m) | C45-01233 | 1,102 | 31 | 961 | 27 | 17.6 | 5.4 |

| 12 ft. (3.7 m) | C45-01234 | 1,400 | 40 | 1,259 | 36 | 20.3 | 6.2 |

| 12 ft. (3.7 m) | C45-01235 | 1,698 | 48 | 1,557 | 44 | 22.9 | 7.0 |

| 12 ft. (3.7 m) | C45-01236 | 1,997 | 57 | 1,856 | 53 | 25.6 | 7.8 |

| 12 ft. (3.7 m) | C45-01237 | 2,295 | 65 | 2,154 | 61 | 28.3 | 8.6 |

| 12 ft. (3.7 m) | C45-01238 | 2,593 | 73 | 2,452 | 69 | 31.0 | 9.4 |

| 12 ft. (3.7 m) | C45-01239 | 2,892 | 82 | 2,751 | 78 | 33.6 | 10.2 |

| 12 ft. (3.7 m) | C45-012310 | 3,190 | 90 | 3,049 | 86 | 36.3 | 11.1 |

| 12 ft. (3.7 m) | C45-012311 | 3,489 | 99 | 3,348 | 95 | 39.0 | 11.9 |

| 60° Hopper Angle | |||||||

| 12 ft. (3.7 m) | C45-01202 | 966 | 27 | 825 | 23 | 18.8 | 5.7 |

| 12 ft. (3.7 m) | C45-01203 | 1,265 | 36 | 1,124 | 32 | 21.5 | 6.6 |

| 12 ft. (3.7 m) | C45-01204 | 1,563 | 44 | 1,422 | 40 | 24.1 | 7.3 |

| 12 ft. (3.7 m) | C45-01205 | 1,861 | 53 | 1,720 | 49 | 26.8 | 8.2 |

| 12 ft. (3.7 m) | C45-01206 | 2,160 | 61 | 2,019 | 57 | 29.5 | 9.0 |

| 12 ft. (3.7 m) | C45-01202 | 2,459 | 70 | 2,318 | 66 | 32.2 | 9.8 |

| 12 ft. (3.7 m) | C45-01208 | 2,758 | 78 | 2,617 | 74 | 34.8 | 10.6 |

| 12 ft. (3.7 m) | C45-01209 | 3,057 | 87 | 2,916 | 83 | 37.5 | 11.4 |

| 12 ft. (3.7 m) | C45-012010 | 3,356 | 95 | 3,215 | 91 | 40.2 | 12.3 |

| 12 ft. (3.7 m) | C45-012011 | 3,655 | 103 | 3,514 | 100 | 42.9 | 13.1 |

| 45° Hopper Angle | |||||||

| 15 ft. (4.6 m) | C45-01532 | 1,386 | 39 | 1,096 | 31 | 16.7 | 5.1 |

| 15 ft. (4.6 m) | C45-01533 | 1,854 | 52 | 1,564 | 44 | 19.3 | 5.9 |

| 15 ft. (4.6 m) | C45-01534 | 2,323 | 66 | 2,033 | 58 | 22.0 | 6.7 |

| 15 ft. (4.6 m) | C45-01535 | 2,792 | 79 | 2,502 | 71 | 24.7 | 7.5 |

| 15 ft. (4.6 m) | C45-01536 | 3,261 | 92 | 2,971 | 84 | 27.3 | 8.3 |

| 15 ft. (4.6 m) | C45-01537 | 3,730 | 106 | 3,440 | 97 | 30.0 | 9.1 |

| 15 ft. (4.6 m) | C45-01538 | 4,199 | 119 | 3,909 | 111 | 32.7 | 10.0 |

| 15 ft. (4.6 m) | C45-01539 | 4,668 | 132 | 4,378 | 124 | 35.4 | 10.8 |

| 60° Hopper Angle | |||||||

| 15 ft. (4.6 m) | C45-01502 | 1,734 | 49 | 1,444 | 41 | 21.6 | 6.6 |

| 15 ft. (4.6 m) | C45-01503 | 2,200 | 62 | 1,910 | 54 | 24.3 | 7.4 |

| 15 ft. (4.6 m) | C45-01504 | 2,666 | 75 | 2,376 | 67 | 26.9 | 8.2 |

| 15 ft. (4.6 m) | C45-01505 | 3,132 | 89 | 2,842 | 80 | 29.6 | 9.0 |

| 15 ft. (4.6 m) | C45-01506 | 3,599 | 102 | 3,309 | 94 | 32.3 | 9.8 |

| 15 ft. (4.6 m) | C45-01507 | 4,065 | 115 | 3,775 | 107 | 34.9 | 10.6 |

| 15 ft. (4.6 m) | C45-01508 | 4,531 | 128 | 4,241 | 120 | 37.6 | 11.5 |

| 45° Hopper Angle | |||||||

| 18 ft. (5.5 m) | C45-01832 | 2,120 | 60 | 1,600 | 45 | 19.0 | 5.8 |

| 18 ft. (5.5 m) | C45-01833 | 2,791 | 79 | 2,271 | 64 | 21.7 | 6.6 |

| 18 ft. (5.5 m) | C45-01834 | 3,463 | 98 | 2,943 | 83 | 24.3 | 7.4 |

| 18 ft. (5.5 m) | C45-01835 | 4,134 | 117 | 3,614 | 102 | 27.0 | 8.2 |

| 18 ft. (5.5 m) | C45-01836 | 4,805 | 136 | 4,285 | 121 | 29.7 | 9.1 |

| 18 ft. (5.5 m) | C45-01837 | 5,476 | 155 | 4,956 | 140 | 32.4 | 9.9 |

| 18 ft. (5.5 m) | C45-01838 | 6,148 | 174 | 5,628 | 159 | 35.0 | 10.7 |

| 18 ft. (5.5 m) | C45-01839 | 6,820 | 193 | 6,300 | 178 | 37.3 | 11.4 |

Notes

| *Approximate Usable Storage Capacity with 30° Angle of Repose |

Brock Industrial Storage BR-1981-202304 (284.54kB)

Brock Industrial Storage BR-1981-202304 (284.54kB) Brock Industrial Storage Unskirted Silos Specs BR-1981-202304 (148.5kB)

Brock Industrial Storage Unskirted Silos Specs BR-1981-202304 (148.5kB)